Custom stickers are a booming market, used in everything from branding and packaging to scrapbooking and stationery. With so many styles available, it’s easy to get overwhelmed when choosing the right type for your needs. That’s why understanding the difference between die-cut and kiss-cut stickers is so important. Each offers a distinct finish, presentation, and user experience, and the choice you make can influence your brand’s perception and product appeal.

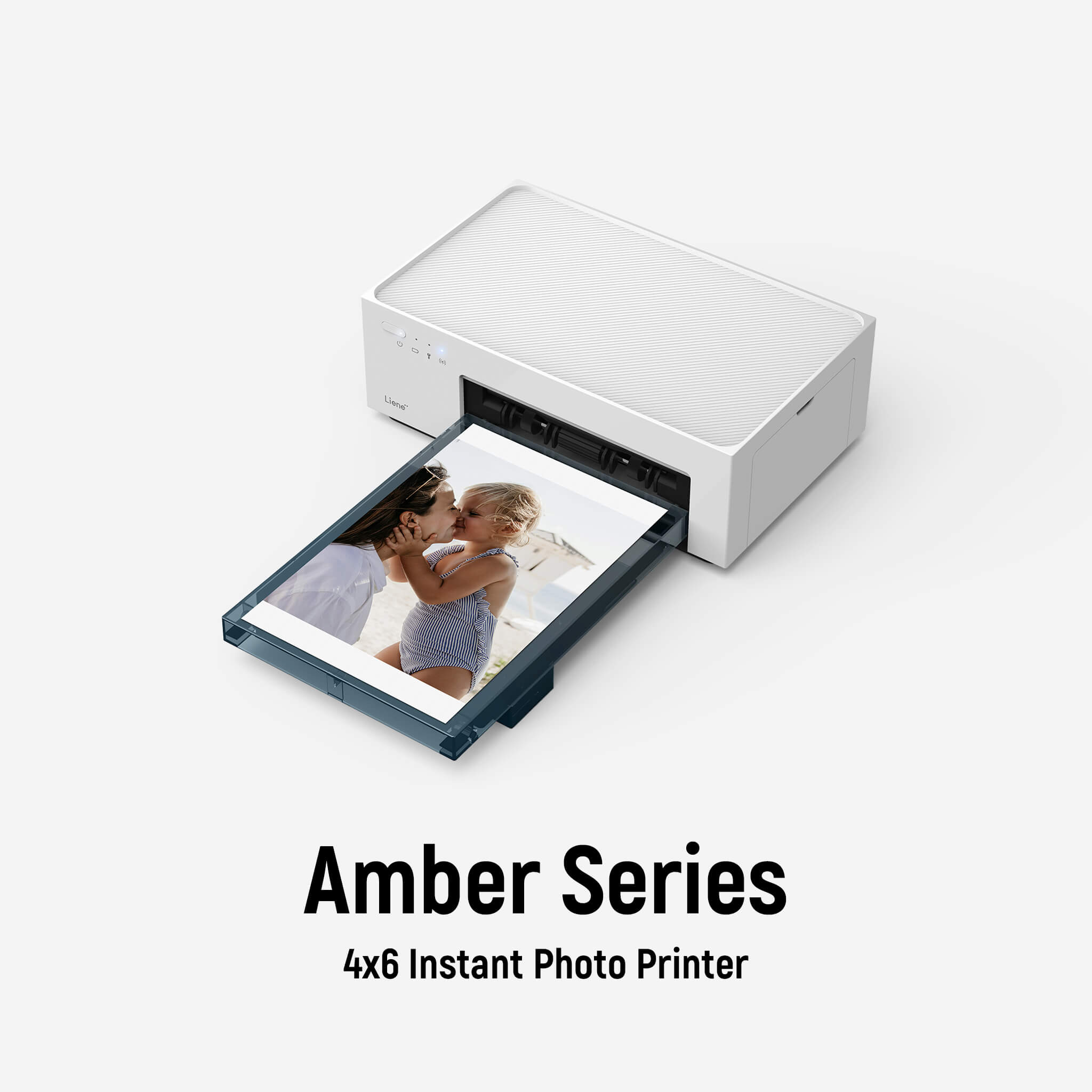

While both serve similar purposes, they differ in shape, cut style, and how they’re handled. The Liene PixCut S1 makes producing either style simple, affordable, and professional-looking. Whether you're a creative hobbyist or running a growing small business, selecting the right cutting method can improve efficiency, reduce costs, and elevate the final product.

Why Knowing the Difference Between Die-Cut and Kiss-Cut Matters

When launching a sticker business or adding custom labels to your product packaging, knowing the difference between die-cut and kiss-cut stickers is crucial. Each type has distinct advantages depending on your goals, aesthetic, and how the sticker will be used.

Die-cut stickers are cut precisely to the shape of your design, offering a bold, standalone look. Kiss-cut stickers, on the other hand, are cut through the sticker layer but not the backing, making them easier to peel and often used in sticker sheets. Choosing the right type ensures a better user experience, packaging presentation, and customer satisfaction.

Matching the sticker style to your brand's vibe can elevate your product line, especially when crafted using the right tools like the Liene PixCut S1.

What Are Die-Cut Stickers?

Die-cut stickers are custom stickers that are cut precisely around the outer edge of the design. The cutting tool slices through both the sticker layer and the backing, giving the sticker its standalone, shaped form without any extra border.

These stickers are commonly used for:

- Logo stickers

- Product branding

- Giveaway promotions

- Laptop or water bottle decoration

Common shapes include circles, squares, or completely custom contours. Die-cut stickers tend to have a premium, professional feel, making them popular among businesses that want a high-impact look.

Industries such as fashion, tech, and personal branding often use die-cut stickers for packaging or customer freebies. The precise edges require a capable cutter like the Liene PixCut S1, which handles tight curves and sharp lines with ease.

What Are Kiss-Cut Stickers?

Kiss-cut stickers are lightly cut through the sticker material, while the backing paper remains intact. This leaves a border around the design, making it easier to peel and handle, especially for intricate shapes or bulk sticker sheets.

They’re ideal for:

- Planner and scrapbook stickers

- Label sheets for product packaging

- Educational tools and activity sets

- Custom sticker packs for reselling and photo display

Kiss-cut stickers can be rectangular, square, or creatively shaped with excess space around the design. That added margin is helpful when offering multiple designs on a single sheet.

Industries like stationery, education, cosmetics, and handmade goods frequently opt for kiss-cut stickers due to their practicality. Using the Liene PixCut S1, users can achieve fine, accurate kiss-cuts ideal for sheeted or roll formats.

Comparing Die-Cut and Kiss-Cut Stickers

Visual Differences and Cut Depth

Die-cut stickers follow the exact contour of the design and are cut through the backing, resulting in a finished product that pops out individually. This gives them a clean, stand-alone appearance that works well for branding and personal use. Kiss-cut stickers have extra material around them, cut only through the top layer, not the backing. This results in a more polished look when stickers are presented in sheets, making them ideal for sticker packs or bulk product labels.

Ease of Peeling and Application

Kiss-cut stickers are easier to peel, especially for delicate or detailed shapes. The backing acts as a support, allowing users to lift the sticker without damaging the edges. This is especially useful for smaller stickers or intricate designs. Die-cut stickers require more care when peeling but offer a sleeker final look once applied, particularly on smooth surfaces like water bottles, laptops, or packaging.

Durability and Material Considerations

Both styles can be made with durable materials like vinyl, matte paper, or waterproof finishes. However, die-cut stickers may experience slight edge wear during shipping due to their exposed shape. Kiss-cut stickers, with their full backing support, often provide more protection during handling and storage, which can be helpful when sending them out in bulk or packing multiple designs together.

Pricing and Production Time Comparison

Kiss-cut stickers can be more economical in bulk production, especially when printed in sheets. They’re often preferred for mass distribution or packaging purposes. Die-cut stickers may take longer to produce if intricate shapes are involved and require more precise cuts. However, using an advanced cutter like the Liene PixCut S1 helps reduce time and waste for both types, making custom sticker production more efficient regardless of style.

How to Create Die-Cut and Kiss-Cut Stickers Using Liene PixCut S1

The Liene PixCut S1 makes it easy for creators of all levels to produce both die-cut and kiss-cut stickers. Here's a simple process to follow:

- Design Your Sticker: Use the Liene App or upload your artwork. Make sure your cut lines are clearly defined using vector shapes or paths.

- Choose Cut Style in the Liene App: The PixCut S1 lets you select between die-cut and kiss-cut options. Choose kiss-cut if you want to leave the backing intact or die-cut for full contour cuts.

- Load the Material: Place your vinyl, sticker paper, or chosen material on the cutting mat. Align it properly and feed it into the machine.

- Adjust Settings Automatically or Manually: The AI-powered system automatically detects material thickness. You can also fine-tune pressure and blade depth manually if needed.

- Start Cutting: With one tap on the app or onboard interface, start the process. The PixCut S1 completes the job quickly with clean edges and minimal errors.

- Remove and Use: Once cutting is done, remove the material. Kiss-cut stickers will stay on the sheet, while die-cut stickers are individually ready for packing or sale.

Why Liene PixCut S1 Is Ideal for Small Businesses and Hobbyists

- Compact Design and User-Friendly Interface

The Liene PixCut S1 fits neatly into small workspaces, making it perfect for home studios, craft corners, or pop-up shops. Its compact footprint doesn’t sacrifice performance, and the intuitive interface requires no steep learning curve. Hobbyists and entrepreneurs can start designing, cutting, and producing within minutes. No advanced setup or technical skills needed.

- Versatility with Different Materials and Cuts

From glossy vinyl to matte sticker paper and even specialty materials like transparent film or holographic sheets, the PixCut S1 handles a wide range of options with ease. Whether you're crafting clean kiss-cut sheets or intricate die-cuts, its AI precision blade delivers smooth, professional-grade results every time, even for detailed or layered designs.

- Cost-Effective Production for Startups

There’s no need to invest in bulky, industrial-level machines or rely on third-party printing services. The PixCut S1 lets users produce high-quality stickers in small batches from home, reducing overhead while keeping quality consistent. This makes it perfect for trial runs, limited-edition drops, and building a product line without overcommitting resources.

- Connectivity and Integration Features

The device connects seamlessly with the Liene App, enabling wireless control, cloud storage access, and easy design editing on the go. Like the Bluetooth printers for iPhone, it offers smooth connectivity and portability, making it easy to manage projects from virtually anywhere. With smart features like preset templates, cut previews, and file syncing, managing orders and workflows becomes streamlined. It’s an all-in-one solution tailored to today’s fast-moving creative businesses.

Conclusion

Both die-cut and kiss-cut stickers offer unique benefits depending on your design and business goals. Die-cut stickers are bold, standalone pieces ideal for branding, while kiss-cut stickers offer flexibility and ease of use, especially in sheets.

The Liene PixCut S1 is the perfect machine to produce either type efficiently and affordably. With precision cutting, easy controls, and versatility across materials, it empowers creators to bring their sticker ideas to life without relying on expensive outsourcing.

Whether you're customizing product packaging or starting a sticker business, the PixCut S1 offers the quality and flexibility needed to make your designs stand out.

Frequently Asked Questions

What is the main difference between die-cut and kiss-cut stickers?

Die-cut stickers are cut through both the sticker and backing, while kiss-cut stickers are only cut through the top layer, keeping the backing intact.

Can the Liene PixCut S1 make both die-cut and kiss-cut stickers?

Yes, the Liene PixCut S1 supports both cutting styles and allows users to switch modes easily via its smart interface.

Which cutting style is better for beginners using the PixCut S1?

Kiss-cut stickers are generally better for beginners because they're easier to peel and produce in batches.

What materials work best for die-cut and kiss-cut stickers with the PixCut S1?

Vinyl, matte and glossy sticker paper, and waterproof label sheets all work well with the PixCut S1 for both cut styles.

laissez un commentaire

Ce site est protégé par hCaptcha, et la Politique de confidentialité et les Conditions de service de hCaptcha s’appliquent.